Aluminium life cycle analysis

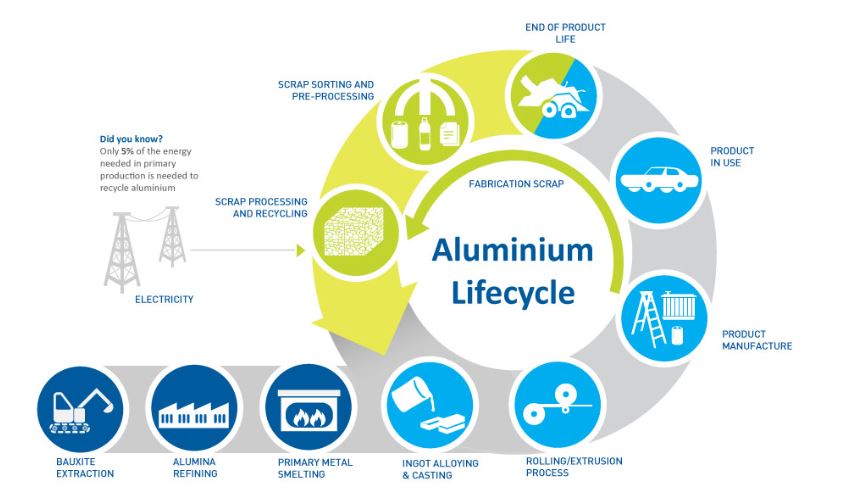

Aluminium’s lifecycle is one of its strongest selling points.

As with all other metals it is extracted from the ore in which it is found and then processed through a number of operations until it is either an end product or a component of an end product.

The beauty of aluminium is that it “lives on” – it can be recycled endlessly back into either the same or other aluminium products.

Not only is the aluminium conserved but the various alloying elements like copper, magnesium, manganese, iron and others are also retained.

The diagram of the lifecycle of aluminium shows how aluminium is conserved and recycled.

-

Bauxite is the ore which contains aluminium. It is found in surface deposits in mainly tropical regions. Aluminium is the third most common element in the earth’s crust.

-

Mined bauxite is refined into alumina – a white powder which is essentially aluminium oxide. Refineries are typically located close to the bauxite mines.

-

Primary smelting is an energy intensive process in which aluminium is extracted from the alumina. The purity of the primary aluminium produced is of the order of 99.5%.

-

Primary metal is alloyed and cast into rolling slab or extrusion billet in a casthouse. Casthouses are typically located at the smelter or at the rolling/extrusion mill.

-

The rolling slab is rolled into specific gauges and widths and heat treated to achieve the engineering properties required. Billet is extruded though a die into a range of shapes or profiles.

-

Manufactures utilise rolled foil, sheet or plate, and extruded profiles to manufacture their specific product – ladders, tankers, beverage cans, foil packaging etc.

-

The product containing the aluminum component remains in use – for short periods of less than 60 days such as in a beverage can or for more than 50 years in the case of aluminium in buildings.

-

In the fullness of time products reach the end of their life and are scrapped

-

Aluminium is recovered from the scrapped end product using a range of mechanical extraction devices – shredders, eddy current separators, air knives etc.

-

The aluminium scrap is processed further to remove contaminants and then melted using the appropriate technology. The resulting aluminium will now be almost identical to primary metal but will still contain valuable alloying elements such as manganese, magnesium, copper, silicon and chrome.

With its superior strength, durability, flexibility and recyclability there’s no reason not to use aluminium for your cladding needs. For more information on what Paneltec can do for you, email [email protected] or call one of our friendly sales representatives on 09 439 4357.

Order Free Samples

Experience and experiment with any of our products first hand in the profile, colour and finish of your choice.

Technical Documentation

View and download product manuals, CAD files, safety data sheets, warranty details, maintenance information and more.