The Best Tooling To Rout And Cut Aluminium Cladding

May 1, 2023

Aluminium cladding is found on many projects in the building industry. It requires low maintenance, is cost effective and is very durable. Its attributes make it ideal to be used as an exterior cladding system in the commercial and residential building industry and also as signage material too. We have teamed up with Tungsten & Tool Ltd, one of the leading cutting and routing specialists in New Zealand, and we are focused on our shared goal to nurture and get a clearer understanding of some challenging details when working with ACM. Below is the different recommendations for each panel type that we supply to the NZ market.

ACM WITH PE (PLASTIC) OR FR (FIRE RATED) CORE

ACM (Aluminium Composite material) and ACP (Aluminium Composite Panel) are two words to describe one type of aluminium panel. ACM or ACP consists of 2 sheets of 0.5mm aluminium surrounding a 3mm core of insulating material.

The materials that typically make up an ACP panel core are polyethylene (PE) and mineral fibre. PE melts at relatively low temperatures and is highly flammable whereas mineral fibre cores often contain hydroxide, a non-combustible material designed to suppress fire spread. This is often known as FR (Fire Resistant) ACM.

ACM claddings with 100% PE cores have contributed to rapid fire propagation on international high-profile buildings such as Melbourne 2014 and Dubai in 2015.

In NZ before an ACM can be used on a building structure its fire propagation and combustibility properties must be defined to meet the NZ building code.

Typically, high percentage PE core ACM don’t meet the building code and are only suitable for signage material.

Caution should be taken when using and specifying ACM products on a building structure in order they comply with the building code. 100% PE core ACMs are less expensive and ok to be used as signage material.

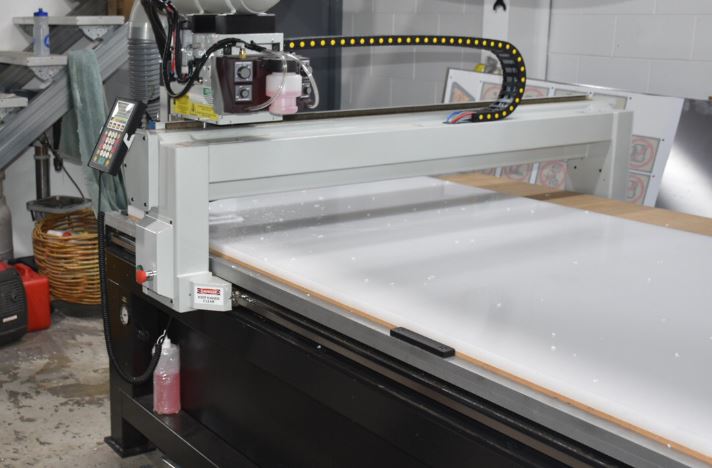

Routing ACM with PE core

Used a lot in the signage industry, the original ACM or Alucobond panel with PE core does bring its own challenges due to the softness of the materials in it and their low melting point.

Here’s an article where Tungsten & Tool Ltd discuss these challenges for routing signage ACM in more detail.

Here’s some of the common challenges:

- Small parts moving on the CNC

- Burr on the top edge or a bad cut edge finish

- CNC cutters not lasting

All these can be addressed by using the correct DLC cutters at the correct, matched RPMs & feed rates.

Routing ACM with Fire Rated Mineral core

Although the material is not hard when compared with materials like steel, the aluminium and mineral core in FR core ACM are extremely abrasive. The core is has mineral salts in the thermos material to help it to prevent the start and reduce the growth of a fire.

These mineral salts wear standard tungsten cutters away very quickly which is why you need to go to the PCD Diamond tipped cutters. Well proved here in NZ, these cutters cut the FR core ACM cleanly and last well.

View the tools from Tungsten & Tool Ltd – HERE.

ALP WITH A PRESSED ALUMINIUM CORE

ALP is two sheets of aluminium surrounding a pressed aluminium core. ALPs are known for their lightweight, rigidity, resistance to oil canning properties while maintaining a 99% or more aluminium composition. ALPs tend to pick up on where the solid aluminium falls short. It is less expensive than solid, unlikely to oil can, lightweight and fully compliant. While it has been widely used in Australia for a number of years, ALPs are rapidly becoming the preferred choice of aluminium cladding in New Zealand.

Routing Pressed Core ACM Cladding

This is successfully routed with single flute upcut cutters. The aluminium is not as gummy enabling a more standard single flute upcut aluminium cutter to be used. The harder aluminium forms a better chip which means that the spiral upcut extracts the swarf out of the cut well leading to less heat build up.

Same as the solid aluminium cladding above, this can be routed dry but a good lubricant will help the tool to cut more freely and last longer.

View the tools – HERE.

Recommended folding tools – HERE.

SOLID ALUMINIUM CLADDING

Solid aluminium is another type of aluminium cladding that is used in the building industry commonly a 3mm panels. Often made from 3003 grade aluminium it provides good resistance to atmospheric corrosion and it’s easy to form while being deemed as non-combustible under AS1530.1 certification.

Solid aluminium while having ease of compliance for any construction project it is the most expensive and heaviest of aluminium cladding. And due to the nature of cold rolled metals it has high tendency to ‘oil can’. But due to its non-combustibility it provides ease of mind and often is the architects choice.

Routing Solid Aluminium Cladding

Usually, the solid aluminium cladding is made from grades of aluminium that are also used in the marine industry. These grades are gummier which can make them a challenge to rout cleanly.

Although it can be routed dry, it is recommended that a cutting lube is used. This will help a lot to reduce heat build up, help to stop the aluminium sticking to the cutter and to help the cutters to last longer.

Although some clients are successfully using single flute upcut cutters, a lot of shops have found better success with the 2 flute slow helix upcut. These cutters cut clean and fast.

View the tools – HERE.

Recommended folding tools – HERE.